The Aspect Plus company is engaged in the supply of spare parts for the travel and swing reducer. We carry out repair of gearboxes with a guarantee.

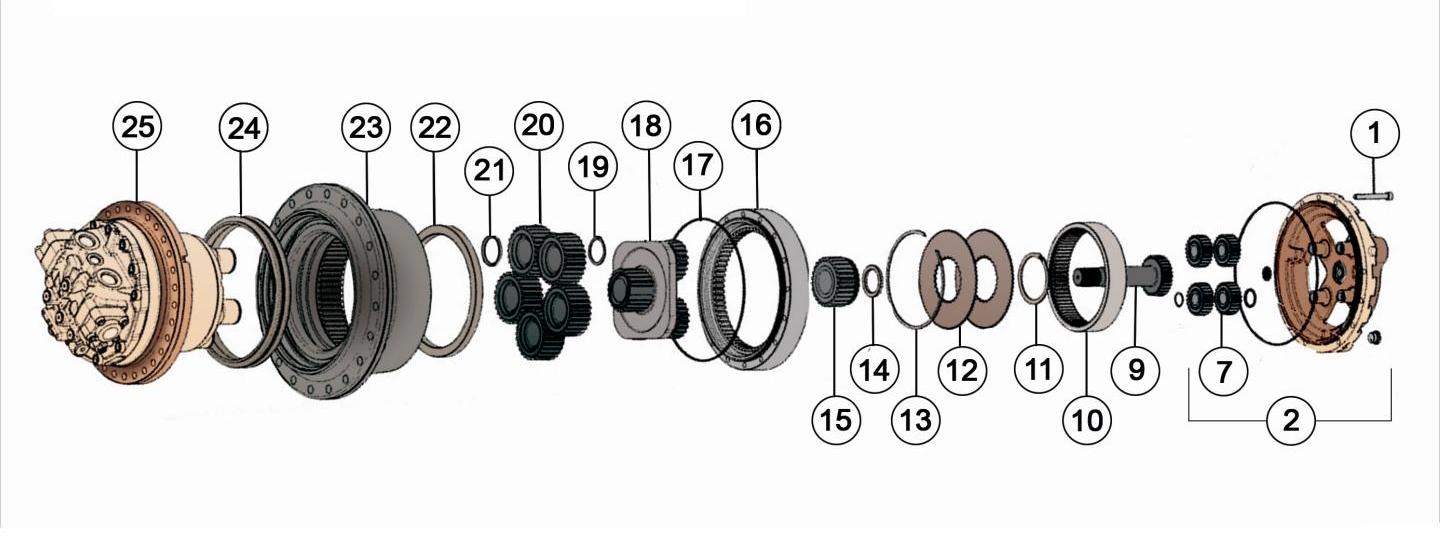

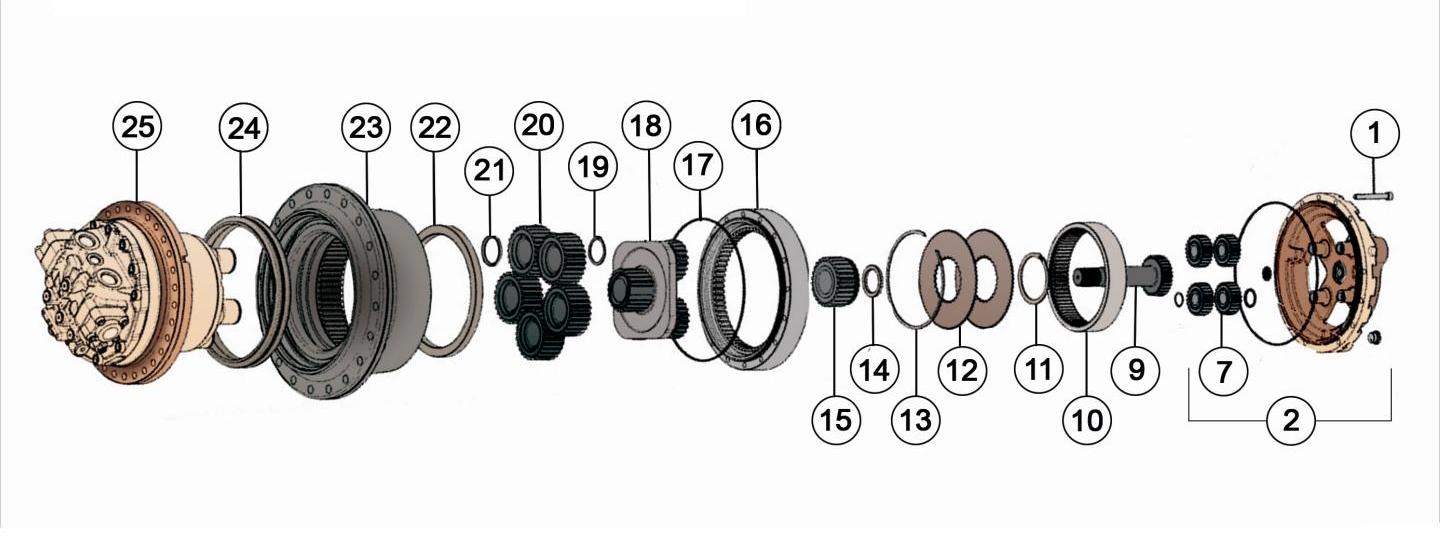

The diagram shows the spare parts that are part of the final drive of the JCB JS220 (200, 210) tracked excavator (Type No. 1):

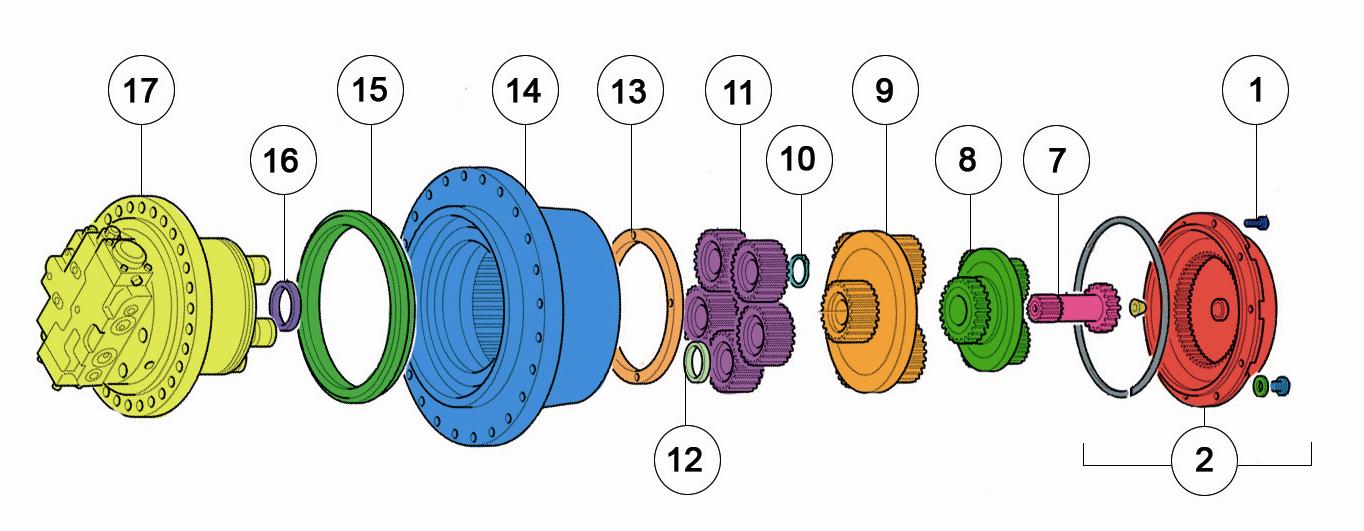

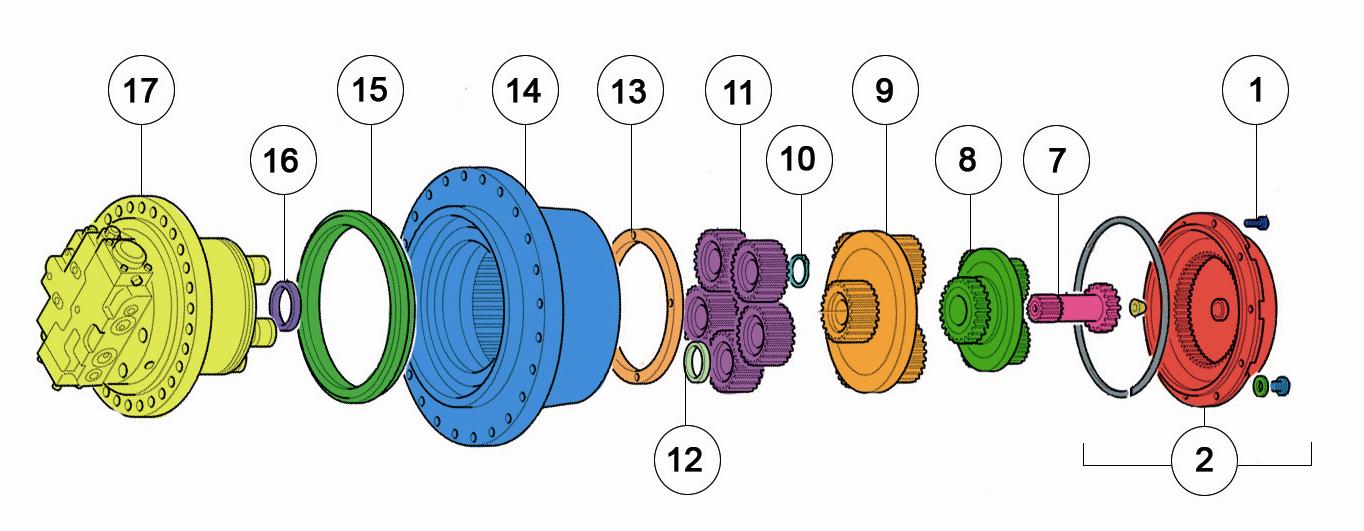

Spare parts for onboard (Type No. 2) for the crawler excavator JCB JS220 (200, 210) in the diagram:

If you have not found the part you need, you can contact us by phone or write a request through the form on the website.

Excavator gearbox parts typically include a variety of components such as gears, bearings, shafts, seals, and gaskets. Some common gearbox parts that are used in excavators include:

Input and output shafts: These are the two main shafts that transmit power from the engine to the hydraulic pump and the hydraulic motor.

Gears: Gears are used to transmit power between the input and output shafts. They come in a variety of shapes and sizes and are made from high-strength materials such as steel or alloy.

Bearings: Bearings are used to support the shafts and gears and to reduce friction. They are typically made from high-quality steel and are designed to withstand heavy loads and high speeds.

Seals: Seals are used to prevent oil from leaking out of the gearbox. They are typically made from rubber or synthetic materials and are designed to withstand high temperatures and pressures.

Gaskets: Gaskets are used to create a tight seal between the various components of the gearbox. They are typically made from materials such as cork, paper, or rubber and are designed to withstand high temperatures and pressures.

Overall, excavator gearbox parts are designed to be highly durable and reliable, as they need to withstand heavy loads and harsh operating conditions. Regular maintenance and replacement of worn parts can help to ensure that excavators operate smoothly and efficiently over the long term.

The gearbox in an excavator plays a critical role in transmitting power from the engine to the hydraulic pump and hydraulic motors that drive the excavator's various movements. Here is a brief overview of how the excavator gearbox works:

Input Shaft: The power from the engine enters the gearbox via the input shaft.

Gears: The input shaft rotates a set of gears that increase or decrease the rotational speed and torque of the output shaft, depending on the excavator's operational requirements.

Output Shaft: The output shaft is connected to the hydraulic pump, which generates hydraulic pressure and flow that drives the excavator's hydraulic motors.

Hydraulic Motors: The hydraulic motors receive the pressurized oil from the hydraulic pump and convert it into rotational motion to drive the excavator's various functions, such as the tracks, boom, arm, and bucket.

Reverse Gear: The gearbox may also have a reverse gear to enable the excavator to move in reverse.

The gearbox also contains other important components such as bearings, seals, and gaskets, which help to reduce friction, prevent oil leakage, and maintain a tight seal between the gearbox's various components. Proper maintenance and regular inspection of the gearbox can help to ensure its reliable operation and prevent costly breakdowns.