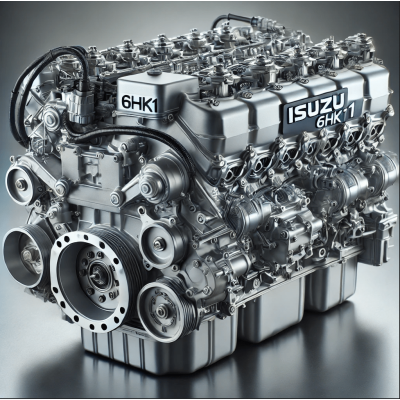

Possible malfunctions of Isuzu 6HK1 engines

Isuzu's 6HK1 engines are one of the most popular diesel engines used in specialty equipment due to their power, efficiency and reliability. They are ideal for heavy-duty applications and those requiring significant power output.

Isuzu 6HK1 engines are installed in heavy and medium-duty excavators, including Hitachi and Isuzu, as well as in quarrying and mining equipment, construction equipment and other machinery.

Despite the reliability of these engines, certain malfunctions may occur during intensive operation or in the absence of proper maintenance of the machines

- Problems with the fuel system:

Problems with the fuel pump: Under high loads, wear and tear on the fuel pump can lead to insufficient fuel delivery, which affects engine performance

Clogged fuel injectors : Due to inadequate cleaning of the fuel filter or use of poor quality fuel, may cause increased exhaust emissions and erratic engine operation

- Engine overheating:

Thermostat malfunction: thermostat stuck in the open position - can cause the engine to overheat

Problems with the radiator: leaking fluids and clogged radiator also lead to poor cooling, causing the engine to overheat

Water pump malfunction: failure of the water pump, which is responsible for circulating the coolant, can also cause the engine to overheat

- Turbine wear

The 6HK1 engine is equipped with a turbocharger, so problems with the turbocharger are possible

Wear of the turbine blades: intensive use may result in reduced turbocharging performance and damage to the blades.

Clogged oil passage: The turbine is a part of the engine that requires a constant supply of oil. If the oil is not flowing properly to the turbine due to clogging, it can cause overheating and damage.

- Oil leaks

Problems with oil seals: over time, oil seals can lose their elasticity and tightness, leading to oil leaks

Wear of gaskets: as the engine operates intensively, gaskets wear out (cylinder head gasket, valve cover gasket)

- Wear of the valve train

Over time, the valves and their seats can wear out. This can lead to compression problems, unstable engine operation, or loss of power.

- Cooling system malfunctions

Radiator clogging: Scale and dirt build up in the cooling system reduces effective heat transfer

Coolant leakage: leaking radiator or damaged hoses can cause insufficient antifreeze and cause overheating

- EGR and possible valve problems

Clogging of the EGR valve: The valve is prone to carbon deposits, which can cause it to malfunction. The engine will not run efficiently and emissions will increase.

- Sensor malfunction

Failure of the temperature sensor and oil pressure sensor:

Oil pressure sensor or temperature sensor malfunction This can cause incorrect signals to be sent to the electronic control unit (ECU), which in turn can lead to incorrect engine operation or an error

- Worn piston rings

Worn piston rings can lead to increased oil consumption, smoke from the exhaust system, and loss of cylinder compression

It is worth knowing to prevent the above breakdowns:

- It is mandatory to use high-quality fuel and oil. This will help prevent contamination of the fuel system and reduce wear and tear on parts

- Inspection of the cooling system. It is imperative to prevent engine overheating, which requires periodic checking and replacement of the coolant

- Regular maintenance. Timely replacement of oils, filters and regular checking of fluid levels will help you avoid most possible malfunctions.