Spare parts ► HPKO/HPK series Hitachi Hydraulic parts

Main advantages of Hitachi HPKO/HPK series hydraulic pumps

Hitachi HPKO/HPK series hydraulic pumps are among the most efficient and reliable devices for hydraulic systems. Here are the main advantages of this series:

- High reliability: HPKO/HPK series pumps are designed using advanced technologies, which allows them to operate in harsh conditions and ensure a long service life without failures.

- Improved performance: Thanks to their advanced design, these hydraulic pumps provide high efficiency, maintaining stable power with minimal energy loss, which increases system performance.

- Energy efficiency: HPKO/HPK series hydraulic pumps consume less energy with high performance, which allows you to reduce operating costs, especially with long-term use.

- Minimal noise and vibration: the special design of these pumps allows for reduced noise and vibration during operation, making them more comfortable to use.

- Robust construction: HPKO/HPK series hydraulic pumps have a b and reliable housing, which allows them to withstand heavy loads and harsh operating conditions.

- Versatility of application: These pumps are suitable for a wide range of applications, including construction machinery, agricultural equipment and industrial systems, thanks to their flexibility in settings.

- Ease of maintenance: Ease of maintenance and the ability to quickly replace worn components make these pumps convenient to maintain in working condition.

- High control accuracy: thanks to advanced technologies, these pumps have a precise control system that allows them to be adapted to different operating conditions and customer requirements.

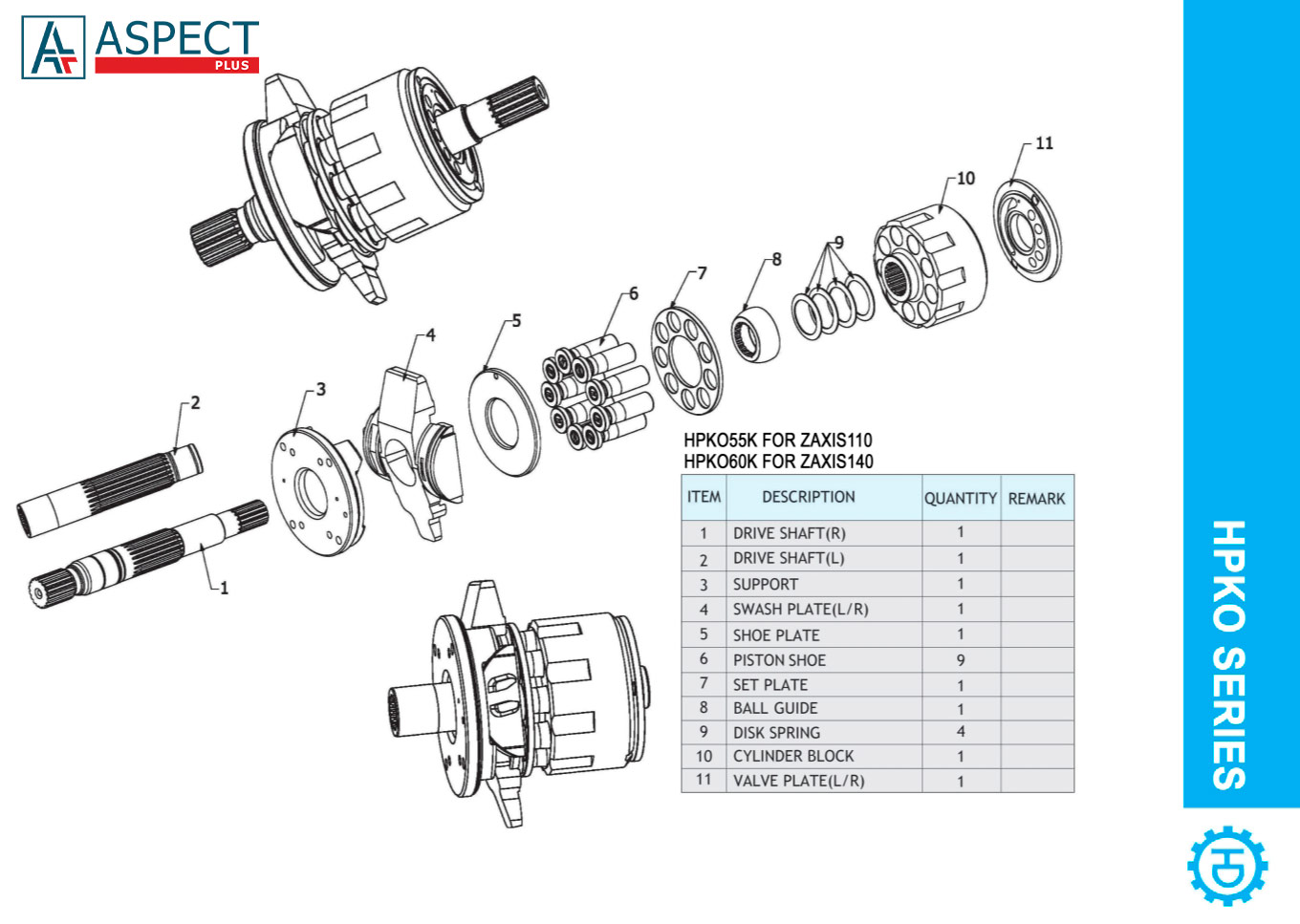

Hitachi HPKO/HPK series hydraulic pumps consist of major components, each of which plays an important role in its operation. The main components of this pump include:

- Cylinder block (Cylinder block Rotor)

consists of several cylinders in which plungers are located, which, moving inside the cylinders, create a variable volume, due to which hydraulic fluid is sucked in and pumped out.

- Driven Shaft

part of the hydraulic system that transmits torque from the drive (for example, from an engine or motor) to the working elements of the hydraulic pump. It provides movement and rotation of the rotor or other moving part of the pump, which allows pumping fluid and creating the necessary pressure in the hydraulic system. The driven shaft must be b and wear-resistant, as it operates under high loads, often in aggressive environments, therefore it is made of special materials that withstand mechanical and chemical influences.

- Hydraulic pump drive shaft (Drive Shaft)

a part that transmits torque from a power source (for example, from an engine or other mechanism) to a hydraulic pump, driving it in motion. It is the main part of the mechanical transmission in a pump, ensuring the rotation of the working parts of the pump, such as the rotor or pistons, to create fluid flow and the necessary pressure in the hydraulic system. The drive shaft is usually made of high-quality materials that can withstand significant loads, mechanical wear and the effects of aggressive fluids with which the pump works.

- Gear pump

A simple and reliable device used to pump liquids. It consists of two gears that rotate inside a housing. When these gears collide, cavities are formed between their teeth, which are filled with liquid. This liquid is then carried to the pump outlet.

- Retainer Plate

an element of hydraulic pumps and motors that ensures tight contact of pistons with a swash plate or other working element, creating sealed chambers for working with hydraulic fluid. It reduces leaks, provides uniform pressure, and promotes stable operation of the mechanism, being made of wear-resistant materials to withstand high loads and friction.

- Shoe plate

an element of hydraulic pumps or hydraulic motors that serves to support and fix other components, such as a cylinder block or piston group, ensuring their stability and correct location during operation. It transfers the load from moving parts to the mechanism body, provides tightness and may have channels for supplying and removing the working fluid. It is made of wear-resistant materials that can withstand high pressures and mechanical loads.

- Piston shoe

a mechanical element commonly used in hydraulic systems to transmit force or motion. The plunger is a cylindrical piston that performs translational motion, and the thrust bearing serves as a support part that reduces friction and ensures uniform load distribution between the plunger and the working surface. Such designs are widely used in pumps and other mechanisms where high precision and durability are required.

- Swash plate (Cam rocker)

a spare part used to provide rotational motion in various machines and mechanisms. It has a design that allows it to rotate around an axis, providing flexibility and mobility to the system. A turntable is often used in lifting mechanisms, cranes, hydraulic installations and machines to perform operations with precise direction or angle changes. Its function is to maintain stability during the rotation of heavy loads or machine parts, reducing friction and ensuring reliable movement.

- Swash plate with Support (right and left)

are elements of mechanisms that provide precise and stable rotation and support for moving parts of machines. A turntable is a structure that allows rotation around an axis, providing movement or changing the angle to perform certain operations, for example, in cranes or machine tools. A caliper, in turn, is a mechanical part that holds and guides a moving part (usually a machining tool or other part) in a given position. Together, these elements are used in many precision mechanisms where stability, accuracy, and the ability to change the direction or position of rotating parts are required.

- Disk Spring

a mechanical system element used to store, transfer, or compensate for forces in the form of elastic deformation. It takes the form of a metal disk with a specific geometry (usually convex or wavy) that allows it to compress or expand under load. Due to their compactness and ability to withstand high forces, spring disks are often used in clutches, shock absorbers, spring washers, and mechanisms for damping vibrations or compensating for gaps.

- Hydraulic pump repair kit (Seal kit)

a set of spare parts and components intended for the restoration or repair of a hydraulic pump. It usually includes seals, gaskets, oil seals, filters, gears, bearings and other components that may wear out during the operation of the pump. Using a repair kit allows you to extend the life of a hydraulic pump without the need for its complete replacement, restoring its performance and efficiency. Repair kits are often supplied by pump manufacturers or specialized companies to support the maintenance of hydraulic systems.

- Valve plate Motor (right and left)

A member used to distribute loads evenly between connected parts or to adjust clearances in machinery. It is installed between mating surfaces, such as under bolts, nuts, bearings, or other components, to reduce friction, prevent deformation of parts, and ensure precise positioning. Spacers are often made of durable materials such as steel or bronze, and are widely used in engines, transmissions, hydraulic systems, and other machine components.

- Cradle support (Support)

a mechanical element that provides support and direction of movement of a cradle (turntable) in various mechanisms and devices. It serves as a support for the cradle, allowing it to perform rotational or angular movements with the necessary accuracy and stability. The caliper also helps reduce friction and wear between moving parts, ensuring smooth operation of the mechanism. It is typically used in hydraulic systems, construction equipment (e.g., in cranes, excavators), and other machines where reliable support of rotating parts is required.

- Ball guide

is a spherically shaped component used to connect or support moving parts of a mechanism, ensuring their smooth movement. It is usually made of metal or other durable material and serves to compensate for irregularities or gaps between parts, reducing friction and wear. Spherical bushings are often used in systems where angular movement or rotation is required, such as in car suspensions, as well as in hydraulic and mechanical systems where stability and ease of installation are important.

- Hydraulic Pump assembly

is a fully assembled and ready-to-use hydraulic unit used to pump fluid under pressure in hydraulic systems. It consists of basic components such as a housing, drive shaft, working elements (gears, pistons or vanes), sealing elements, bearings and covers. Such a pump provides fluid flow and transmission of hydraulic energy to operate actuators, for example, in construction, agricultural, industrial machinery or vehicles. The pump assembly is supplied as a single unit for easy installation and quick replacement.

- Oil Seal

a sealing element used to seal joints between moving and stationary parts of mechanisms, preventing the leakage of liquids or gases and protecting the components from dust, dirt or moisture. Oil seals are usually made of elastic materials such as rubber, silicone or polyurethane, and have metal or rigid reinforcement to ensure strength. They are widely used in various technical components, for example, in engines, hydraulic systems, transmissions and bearings, ensuring long-term and efficient operation of mechanisms.

- Separator (Fuel filter)

a component used to separate different substances, materials or phases in mixtures. Depending on the purpose, separators can separate solid particles from a liquid or gas, liquid components of different densities or gaseous mixtures. For example, in bearings, a separator holds and separates rollers or balls, ensuring their uniform movement and reducing friction. In hydraulic or industrial systems, separators are used to clean oil, water or air from impurities. They are important elements in many industries, including mechanical engineering, petrochemical, food and medical industries.

We also provide repair services for Hitachi motors and pumps, guaranteeing the quality of the work performed. We are ready to provide a high level of service to our customers.

You can always contact Aspect Plus specialists for help in selecting the necessary spare parts for your hydraulic pump, get advice and additional information regarding technical units and other components.

Contact our managers if you have any questions! Or leave your contact details - we will call you back as soon as possible!

We are waiting for your orders! We will be happy to cooperate!

Used in: Hitachi ZX120, Hitachi ZX110, Hitachi ZX130, Hitachi ZX135, Hitachi ZX125