Spare parts ► M5X series Kawasaki Hydraulic parts

Main advantages and scope of application of Kawasaki M5X series hydraulic motors

The Kawasaki M5X series of hydraulic motors are variable displacient axial piston motors with a swash plate, specifically designed for swing motors in heavy construction and mining applications. The M5X series is the flagship evolution of the M2X and M3X, with maximum power, precision and durability. These hydraulic motors are the ideal solution for tough applications where smooth turning, control, power and long service life are required.

Kawasaki M5X series hydraulic motors are:

- Maximum reliability and power

- Smooth torque control

- High wear resistance

- Minimum noise level

Main advantages of Kawasaki M5X series hydraulic motors:

- High pressure and power

- Working pressure: up to 350 bar, peak pressure - up to 400 bar.

- High output torque, allowing for efficient rotation of large superstructures under load.

- Variable displacient

- Automatic or manual volume control allows:

- Increase energy efficiency

- Smoothly change rotation speed and torque

- Reduce systi load during start/braking

- Integrated safety valves

- Brake valve — for safe and stable stopping of the turn.

- Anti-cavitation valve (anti-cavitation) — protection against the formation of cavities and damage during a sudden change in load.

- Increased wear resistance

- All components are made of high-quality alloy materials, designed for intensive use in aggressive conditions (dirt, sand, high tiperatures).

- Long service life without major repairs.

- Low noise and vibration levels

- Thanks to the new cylinder block design and hydraulic pulse damping, the engines operate quietly, which improves operator comfort.

- Compactness and modularity

- Despite the high power, the units have relatively small dimensions.

- Easy installation in standard locations without additional modifications.

- High control precision

- Instant response to changes in load and control signals.

- Ideal for digital and proportional control systis, including CAN buses.

- Easy to maintain

- The modular design allows for quick disassibly and replacient of components.

- Compatibility with modern diagnostic systis.

Areas of application of Kawasaki hydraulic motors M5X series:

- Heavy-duty excavators (30–80+ tons)

- Quarrying and mining equipment

- Rotary mechanisms of drilling rigs and cranes

- Specialized heavy equipment with intensive cyclic work

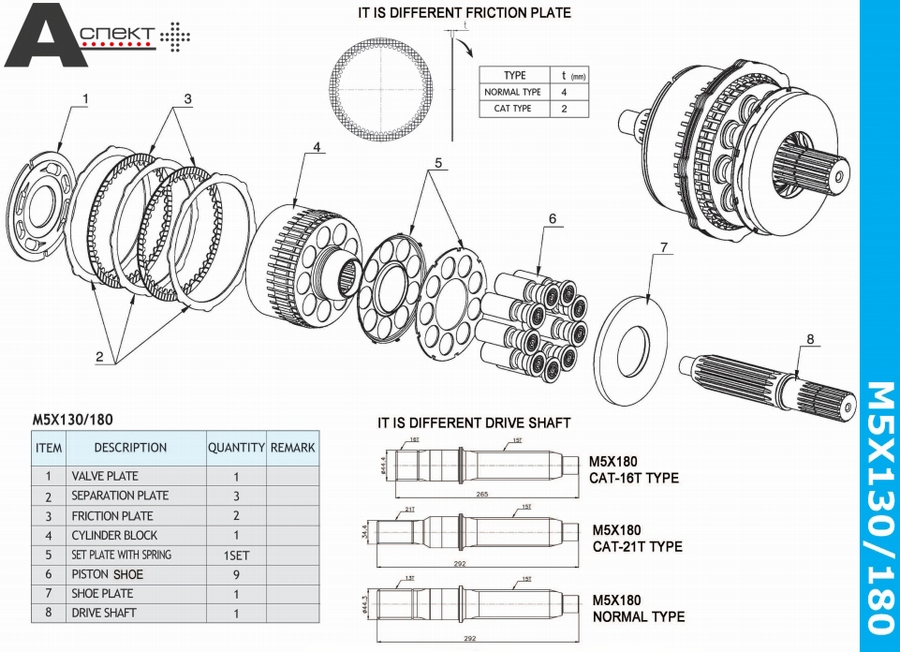

Kawasaki M5X series hydraulic motors consist of major components, each of which plays an important role in its operation. The main components of this motor include:

- Cylinder block Rotor

- Drive Shaft motor

- Ball guide

- Screw

- Separation Plate

- Friction Plate

- Disk Spring

- Snap Ring

- Valve Relief

- Pressure Override Valve

- Slider

- Hydraulic motor Cover

- Coupling of drive Shaft

- Cylinder block press Pin

- Center Pin Disk type

- Center Pin Spring type

- Roller Bearing

- Needle Bearing

- Cradle Bearing Cage

- Cradle Bearing Set

- Retainer Plate

- Shoe plate

- Swash plate (Cam rocker)

- Piston shoe

- Spring of Rotor

- Spring of Ball guide

- Spring for Center Pin

- Control Valve Regulator

- Seal kit motor

- Shaft Seal

- Servo Piston

- Wire

- Solenoid

- Fix Plate of Retainer Plate

- Valve plate Motor

- Valve plate Left

- Valve plate Right

- Ball guide Washer

- Washer

We also provide repair services for Kawasaki engines and pumps, guaranteeing the quality of the work performed. We are ready to provide a high level of service to our customers.

You can always contact Aspect Plus specialists for help in selecting the necessary spare parts for your hydraulic motor, get advice and additional information regarding technical units and other components.

Contact our managers if you have any questions! Or leave your contact details - we will call you back as soon as possible!

We are waiting for your orders! We will be happy to cooperate!

Used in: Hitachi ZX330, Hitachi ZX270, Hitachi ZX280, Hitachi ZX350, Hitachi ZX370