Spare parts ► HMF-02 Fixed displacement motors Linde Hydraulic parts

Main advantages and scope of application of Linde HMF-02 hydraulic motors

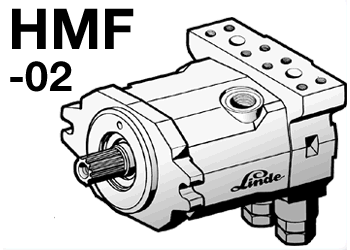

Linde HMF-02 hydraulic motors are fixed displacient axial piston motors designed for closed hydraulic circuits that deliver maximum performance, efficiency and controllability in the most dianding operating conditions. They are the next generation after the HMF-01 with an improved design and expanded capabilities.

Key benefits of Linde HMF-02 series fixed displacient hydraulic motors:

- High energy efficiency

- The optimized design of the hydraulic unit ensures minimal hydraulic losses and high efficiency.

- Less energy consumption means fuel savings and reduced costs.

- Improved dynamics and fast adjustment

- Instant response to load changes.

- Smooth and precise control of the delivery volume ensures precision during maneuvers, especially in hydrostatic transmissions.

- Compact and modular design

- Simplified installation in confined spaces.

- Easy maintenance thanks to modular component structure.

- High pressure and load capacity

- Working pressure up to 500 bar (peak up to 550 bar).

- Suitable for the most energy-intensive mobile equipment and systis that operate at maximum loads.

- Reliability and durability

- Wear-resistant materials and reinforced construction guarantee a long service life even in the harshest conditions.

- Resistance to overheating, dirt, high loads and vibrations.

- Direction of rotation:

- Reversible - can work in both directions

- Control options

- Support for a wide range of control systis:

- EDC (electronic control)

- LR (Load Sensing)

- DR (pressure/flow)

- This makes it possible to integrate the motor into intelligent control systis.

- Support for a wide range of control systis:

- Low noise level

- Improved internal geometry ensures quieter operation, which is important for mobile equipment in populated areas or in production.

Areas of application of Linde HMF-02 hydraulics:

- Hydrostatic transmissions for mobile equipment

- Excavators, combines, snow rioval equipment, cranes

- Construction, agricultural, municipal, forestry equipment

- Machines that require high precision and dynamics in a closed hydraulic circuit

Linde fixed displacient hydraulic motors HMF-02 seriesconsist of major components, each of which plays an important role in its operation. The main components of this motor include:

- Cylinder block Rotor

- Drive Shaft motor

- Ball guide

- Screw

- Disk Spring

- Snap Ring

- Pressure Override Valve

- Slider

- Coupling of drive Shaft

- Center Pin Disk type

- Center Pin Spring type

- Roller Bearing

- Cradle Bearing Cage

- Cradle Bearing Set

- Retainer Plate

- Swash plate (Cam rocker)

- Piston shoe

- Spring of Rotor

- Spring of Ball guide

- Spring for Center Pin

- Control Valve Regulator

- Seal kit motor

- Shaft Seal

- Servo Piston

- Wire

- Solenoid

- Fix Plate of Retainer Plate

- Valve plate Left

- Valve plate Right

- Ball guide Washer

- Washer

We also provide repair services for Linde motors and pumps, guaranteeing the quality of the work performed. We are ready to provide a high level of service for our customers.

You can always contact Aspect Plus specialists for help in selecting the necessary spare parts for your hydraulic pump, get advice and additional information regarding technical units and other components.

Contact our managers if you have any questions! Or leave your contact details - we will call you back as soon as possible!

We are waiting for your orders! We will be happy to cooperate!